The terminal connector attaches the wires to the terminal block. It is necessary to connect the various circuits of the system together and provide the electrical ground for the circuits.

Contents

Definition of terminal

The male terminal is used to match the male connector, and the female terminal is used to match the female connector.

The size of the terminal

That is, the width of the male terminal when the male and female terminals match.

| ID | Decimal (inch) | Tab Width (mm) | Imperial Fraction (inch) |

| 025 | 0.025 | 0.64 | 1/40″ |

| 030 | 0.03 | 0.8 | |

| 040 | 0.04 | 1.0 | 1/25″ |

| 048 | 0.048 | 1.2 | |

| 050 | 0.05 | 1.3 | |

| 055 | 0.055 | 1.4 | |

| 060 | 0.06 | 1.5 | 1/17″ |

| 070 | 0.07 | 1.8 | |

| 090 | 0.09 | 2.3 | |

| 110 | 0.11 | 2.8 | 1/9″ |

| 187 | 0.187 | 4.8 | |

| 240 | 0.24 | 6.0 | |

| 250 | 0.25 | 6.3 | 1/4″ |

| 312 | 0.312 | 8.0 | |

| 375 | 0.375 | 9.5 | 3/8″ |

Common mechanical properties of terminals

- Vertical force. The force is exerted vertically by the female terminal on the male terminal (usually in g).

- Inserting force. The force is applied when a terminal is inserted.

- The terminals overlap or the meshing length. USCAR design requires that the minimum should be 1mm.

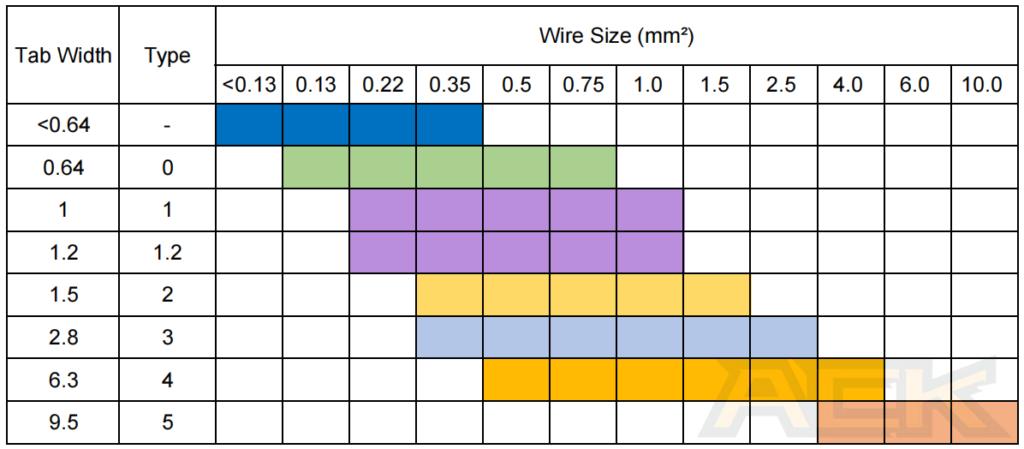

The wire diameter of the terminal matching

Wire diameter, that is, the cross-sectional area of the conductor in the wire.

| Terminal Size (tab width:mm) | Matching wire diameter (mm²) |

| <0.64 | <0.35( <0.13, 0.13, 0.22, 0.35 ) |

| 0.64 | 0.13-0.75 |

| 1 | 0.22-1.0 |

| 1.2 | 0.22-1.0 |

| 1.5 | 0.35-1.5 |

| 2.8 | 0.35-2.5 |

| 6.3 | 0.5-4.0 |

| 9.5 | 1.0-4.0 |

| Terminal Size (tab width:mm) | The current that can be carried (A) |

| 0.64 | < 3A |

| 1 | < 6A |

| 1.2 | < 8A |

| 1.5 | < 10A |

| 2.8 | < 20A |

| 4.8 | < 35A |

| 6.3 | < 50A |

| 9.5 | < 70A |

For example, the cross-sectional area of the terminal size 2.8 is

2.8mm(terminal width) x 0.8mm(terminal height) =2.24mm2

For a conductor size of 2.5mm2(approximate), the current carrying capacity of the terminals is <20A. The size of the wire must match the terminal system being used.

Correct orientation for terminal

Only the correct orientation terminal can be inserted into the connector holes.

Sealing Type

Mat Seal

Advantages

1.It can meet the assembly of small spacing or small density.

2.The terminal only needs to press the wire.

Disadvantages

1.The diameter of the wire must be carefully treated when matching the connector seal.

2.Unused holes should be placed in a blind plug to maintain the sealing effect.

3.The connector needs a cover to ensure the Lateral load of wire.

Single Wire Seal

Advantages

1.Unused holes are easily blocked (usually using cavity plugs or sticks).

2.The size of the wire can be easily changed

Disadvantages

1.It is difficult to press the seal to the terminal.

2.The size of the sealing plug must match the size of the wire.

Terminal Type

Non-waterproof terminal

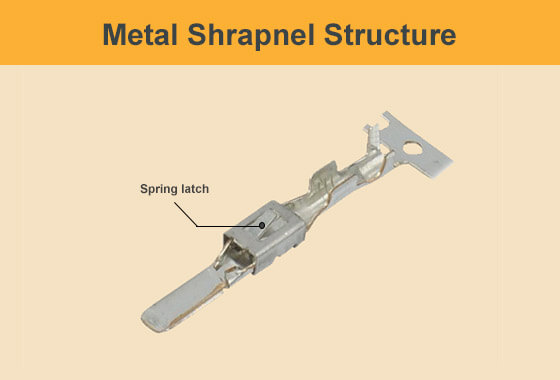

Metal shrapnel structure

Generally, there is metal spring latch on the terminal, which is generally 1 or 2 pieces of design. Europe is more likely to use terminals of this design.

Without Metal shrapnel structure

The elastic structure is in the connector. The terminal is designed without metal shrapnel structure. Generally speaking, the United States and Japan prefer to use such terminals.

Waterproof Terminal

The single wire seal is pressed to the terminal.

Comparison

The advantages of spring latch on terminal

1.The holding force of terminals and connectors is higher

2.Tactile and auditory responses are higher when the terminal is plugged into the connector.

3.Metal shrapnel is more secure to prevent the operator from withdrawing the terminal with the wrong rework tool.

The advantage of the elastic structure is adopted on the connector housing is the insertion force of the terminal is smaller.

If you’d like to know more about elastic structure design on the terminal/connector housing, we suggest you read this article, “Why did the connector terminal fall off?” which talks about this.

One Response