Electrical connectors are an essential part of electric or electronic devices and circuits. If you are designing hardware, re-wiring a car, or working on an electrical project, you know it. Here you will find a guide to help you choose the right connector for your project.

Below you will find some technical aspects to help you choose the best connector/s for your project.

What to bear in mind when choosing an electrical connector

Contents

Electrical needs

Current rating

This is one of the most important things you need to consider when you are choosing a connector. You need to know how much current (measured in Amps) is going to flow through it. You have to use a connector capable of handling that current to achieve a good connection. Electrical connections produce heat. Choosing a proper connector will ensure a safe operation.

Operating Voltage

You need to know how many volts are going to run through the connector. This will enable you to choose a model capable of providing adequate isolation. Low-voltage connectors don’t need to have the same safety features as high-voltage connectors.

Number of contacts needed

Take a look at the circuit; count how many electrical sources and grounds it has. If you have signal wires, take note of the voltage levels they are going to be handled. With that information, you can make a layout of the pinout you are going to need.

Termination types

Wire-to-wire: these connections connect a wire or a group of wires to another wire or group of wires.

Wire-to-board: this is when you need to connect a wire or a set of wires to an electronic circuit. For example, most modern cars have a wire that connects the throttle pedal to the engine computer. Another set of wires goes to the throttle body. These three components have internal PCBs (Printed Circuit Board). If you are designing a device, you will have to determine which connectors will be the male and the female. You may have to check if there are any norms and industry standards for the kind of part you are designing.

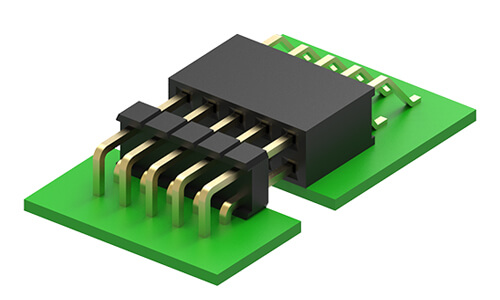

Board-to-board: these connectors connect components or even other boards to a PCB. For example, if you need to connect an LCD screen to a circuit board, you will need one of these. There are many types of board-to-board connectors. You will have to think about what’s best for practical purposes. For example: are you going to use a flat wire, like a flex, or are you going to attach the components piece-to-piece?

Check for space constraints and practicality

There are many factors that you need to bear in mind when you are choosing a connector for your project. Space and location considerations are almost as important as your electrical needs.

You have to be aware that a connector takes up space, and it’s going to need extra room for plugging it in and out.

By way of advice: try to think how often you or a technician will need to plug and unplug that connector. If the part will need frequent plugging and unplugging, try to leave enough room to make the job easier. The technicians will be thankful for your consideration.

Connector size

If you are not going to have much space, you may need a small connector.

There is a concept called “Circuit density”. It states the number of circuits that an electrical connector can house per square inch.

Knowing the “circuit density” you need will help you narrow your search. Connectors’ manufacturers usually state the circuit density of their products’ datasheets.

Wire of cable size

The wire gauge (diameter of the wire) is also an element that affects the size of a connector. If you have a thick wire, you will need a socket large enough to accommodate the wire in the correct way.

Engagement force

It’s the effort required to plug or engage an electrical connector.

It’s often measured in pounds/circuit. This value is important in high circuit count electrical connectors, and it’s often measured in pounds/circuit. This value takes more relevance in connectors with a high circuit count. It’s also important when it’s necessary to plug a pin header connector into a printed circuit. If the connector is too strong, pulling from it to disconnect it could damage the circuit board. The same goes for hard-to-reach connectors; you have to foresee how necessary it will be to use them. A connector with a high engagement force is going to be harder to disconnect.

Reliability needs

Mating cycles

This Is the number of times it’s safe for a connector to be coupled and uncoupled from its counterpart or socket. You will have to think about how many couplings your connector will have to endure in its lifetime. Knowing this will help you choose the strength of the connector and other features.

Housing lock type

It’s important to know how much stress the mated electrical connectors will have to resist. High vibrations and axial loads, for example, can loosen or even detach a connection. That’s when “positive locking” electrical connectors come into place. These connectors have a locking device that prevents accidental disconnections. There are many kinds of locking types on the market for every need and application.

Environmental sealings

Depending on the connector’s location, you may need to use sealed connectors. Sealed connectors keep away damaging elements like water, dust, dirt, etc. There are different models of sealed connectors offering different levels of protection.

Operating temperature range

You have to know in what environment your application is going to be working. Component manufacturers usually include the temperature ranges of their components in their datasheets.

Automotive components usually have operating temperature ranges from -40 °C to 125 °C.

It’s up to you to determine which specs best suit your device.

Other important things to bear in mind

Flame retardant requirements

Connectors’ manufacturers usually make their products with flame-retardant materials such as nylon plastic. Most of the materials used in connectors are UL94V-2 and 94V-0 compliant. In case of fire, a 94V-0 rated material will extinguish itself faster than a 94V-2. For most applications, a 94V-2 material is enough to make a product safe.

Housing materials

The housing materials mainly depend on the environment where the connectors are going to be used. PA6 and PA66 nylon, PBT, ABS, and PC (polycarbonate), are the most used materials on connector housings. The aspects to bear in mind when choosing a housing material are listed below:

●Resistance to environmental exposure. This includes chemicals, UV exposure, and heat exposure.

●The temperature of the soldering process. They have to be able to endure the heat produced by this process.

●Strenght. They have to endure normal and some abusive use.

●Operational temperatures

●The connector’s complexity. For example, if it needs to have moving parts such as latches for mating and/or contact retention.

●Insulation requirements.

●Material costs.

Strain relief

This feature offers an extra degree of safety. It prevents a “live” wire from touching other wires or “ground/neutral” sources. This could happen, for example, when someone or something pulls a wire by accident.

Pin and plating materials

Connectors’ pins and platings come in different materials. These materials need to be very conducive to reduce heating and improving the current flow. They also protect the pins from corrosion and wear caused by time and mating cycles. One of the most used materials in the industry is copper and its alloys. Copper-Zinc alloys are often used in the automotive industry. Cooper-Nickel-Silicium alloys have recently come into use. This particular alloy handles higher amps and temperatures than Copper-Zinc alloys. The most frequent plating materials are gold, silver, tin, and its alloys.

Tin-plated terminals are good enough for many standard applications with low mating cycles. They don’t handle high temperatures and vibrations well. A better option is Tin/lead, as it can endure more mating cycles and stand temperatures better.

Silver-plated terminals are great for high voltage systems. But they are not suitable for applications with working temperatures above 140-160 °C.

Gold-plated terminals endure extreme electrical conditions and great for transmitting signals or data. They respond to signals with small voltage levels and can manage high data rates. They endure extreme environmental conditions like high temperatures above 150 Celcius degrees. They can also stand hard vibrations and almost infinite mating cycles.

Price and delivery

The price of electrical connectors is not only the cost of the housing and the terminals. You also have to consider the cost, time, and labor to attach the wires to each terminal. Don’t forget that each terminal goes inside the housing, and it may need soldering to attach it to the PCB. There are lots of tools, ranging from manual crimp tools to big machines built for mass production.

If you are aiming for mass production, don’t underestimate the time and assembly cost. Don’t focus on the connector price itself. A connector that may sound expensive will be easier to assemble, saving your company a lot of time and money. You also have to think about storage space and stocking. Try to find standard connectors (there are more than 30,000 models available on the market). Standard connectors offer plenty of benefits:

– they are easier to replace than custom connectors.

– they are parts that meet most Countries’ regulations.

– Most of them are easy to find.

Try to buy your connectors from a well-known company that holds a large stock of the pieces you need. This will save you a lot of time by having your parts delivered faster to you.

– If you can’t find a standard connector to suit your application, you will need to design it yourself. You could also hire a well-known connector manufacturer to design it and produce it for you.

I hope this list has been useful for your project. If you can, try to take notes of these items before starting to look for a connector.

It’s going to help you to narrow down your search. Choosing the right connector will make your device easier to mount and to service. Besides, it will show your customers that your product has a serious design and will help you have a neat and well-sorted electrical installation. Choose the current ratings well, and don’t forget to keep it easy for anyone needing to plug your device in and out. About costs and simplicity, try to use a well-proven connector that is already on the market. Use a custom-designed connector only if necessary or if you want to give your product a special touch. If you feel that by doing so, you are going to make it stand out among competitors’ products, then go ahead.