Vehicle wiring harness connector is an important part of the automobile. It is connecting the connection points of the automobile circuit. Its quality directly affects the transmission effect of electric power or signal. The proportion of the cost of the connector in the car is small. However, if the quality problem occurs in the use of the car, it often leads to serious consequences. And the maintenance cost increases significantly. Therefore, the quality of connectors is getting more and more attention from automobile manufacturers and parts suppliers.

The terminal fall-off is a common failure mode of automotive wiring harness connectors. It refers to the abnormal separation of the terminal and housing after the connector is assembled. Which leads to the loss of the connector function. The causes of this failure generally include three aspects:

1. The holding force of the terminal in the housing is not qualified;

2. Opposite plug interference;

3.Product application problems.

We will analyze the fall-off of the terminal and propose a solution regard to these three reasons.

Contents

The holding force of the terminal in the housing is not qualified

The holding force of the terminal in the housing is the force required to detach the terminal from the housing in the axial direction. To avoid the phenomenon of the terminal fall-off, the performance test standard of the connector has made strict provisions on the holding force of the terminal in the housing.

① The holding force of the connector terminal with specifications no more than 2.8mm (Tab Width) is greater than 40N;

② The holding force of the connector terminal size greater than 2.8mm is greater than 60N.

Generally speaking, there are 2 reasons for the unqualified holding force of the terminal in the housing. Structural design problems and material selection problems.

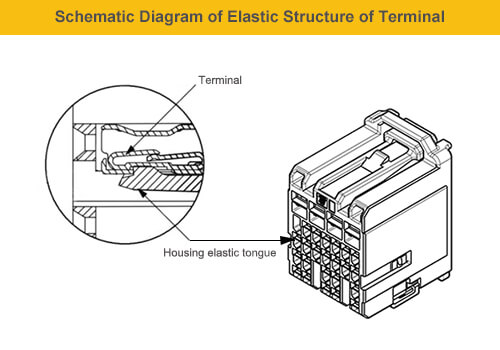

The elastic structure is adopted on the connector housing

The elastic structure required for terminal and housing assembly is designed on the housing. The terminal and the housing assembly are realized through the deformation of the housing elastic tongue. After the terminal and the housing are assembled in place, the housing elastic tongue will be restored to the original state due to the lifting of the force. The coordination of the housing elastic tongue and the hanging structure designed on the terminal can ensure the effective positioning of the housing to the terminal.

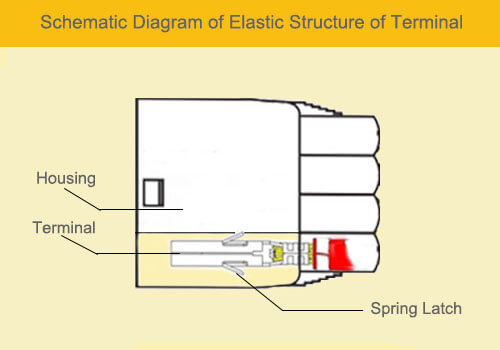

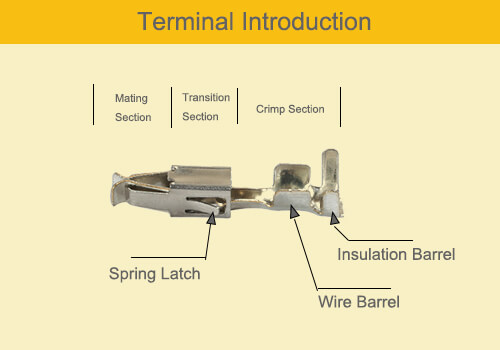

The Terminal Adopts Elastic Structure

The elastic structure on the terminal means that the elastic structure is designed on the terminal. The terminal and the housing assembly are realized through the force deformation of the spring latch (the elastic structure designed on the terminal). After the terminal and the housing are assembled in place, the spring latch at the terminal is restored to its original state due to the lifting of the force. The coordination of the spring latch and the hanging platform structure designed on the housing ensures the effective positioning of the housing to the terminal.

Selection of Connector Housing Material

The connector commonly used materials are polyamide (commonly known as nylon), polybutylene terephthalate (PBT), ABS, etc. For the housing elastic tongue structure, the material’s toughness is generally considered. The size of the elastic tongue structure is designed according to the material that meets the toughness requirements.

Terminal Material Selection

The commonly used materials of connector terminals are red copper, brass, and bronze. According to their hardness, they can be divided into three soft, semi-hard, and hard states. Among these 3 materials, copper is commonly used in grounding hole or fork joints. Brass and bronze are widely used. Brass conducts electricity better than bronze, while bronze has better hardness and elasticity than brass. When the terminal bullet tongue structure is used, bronze should be generally used. There is often insufficient holding force in the use of brass material.

Opposite Terminal Interference

Opposite terminal interference refers to the failure of the plug in the process of male terminals inserting into the non-effective area of female terminals. Resulting in the loss of functions such as terminal fall-off.

Generally speaking, the reasons for opposite terminal interference are structural design problems; Terminal insertion-withdrawal force problems.

Structural Design Problems

The structural design of the connector involving the interference of the male terminal to the female terminal mainly includes:

- The center distance design of the connector (including size error or excessive tolerance, etc.);

- The space design of the terminal and the housing (including too large or too small clearance), etc

Terminal insertion-withdrawal force problem

Due to assembly performance requirements, the smaller the terminal insertion-withdrawal force should be, the better. If the plug force is too small, the contact resistance of the plug will increase, and the electrical conductivity will decrease. Therefore, the appropriate terminal insertion-withdrawal force needs to meet the requirements of the assembly performance of the connector. But only if the performance of the connector is guaranteed. To improve the electrical conductivity of terminals, the insertion-withdrawal force of terminals is often increased in practice. Which generally leads to assembly difficulties. When the insertion-withdrawal force of the terminal is greater than the holding force of the terminal in the housing, it may cause the terminal to drop out in the insertion process of the socket to plug.

Product application problems

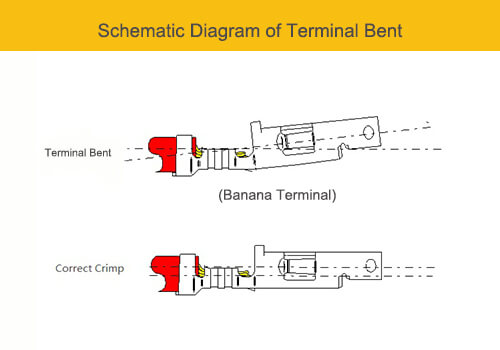

The application problem of the connector terminal fall out mainly refers to what may cause the terminal fall out in the wire harness production process. Which generally include the terminal crimping problem and terminal assembly problem. The banana terminal is a common problem in the process of terminal crimping. It refers to the excessive bending of the terminal caused by improper crimping. So that the centerline of the joint area and the crimping area of the terminal not parallel. If the degree of excessive bending is light, the insertion-withdrawal force of the connector will increase. And the assembly performance will be affected. If the degree is serious, the male terminal cannot be inserted into the effective insertion area of the female terminal in the insertion process of the plug-to-plug. Thus causing the terminal to fall out.

Conclusion

In practical use, if there is a terminal fallout, we should first analyze the causes of the problem and solve it pertinently.